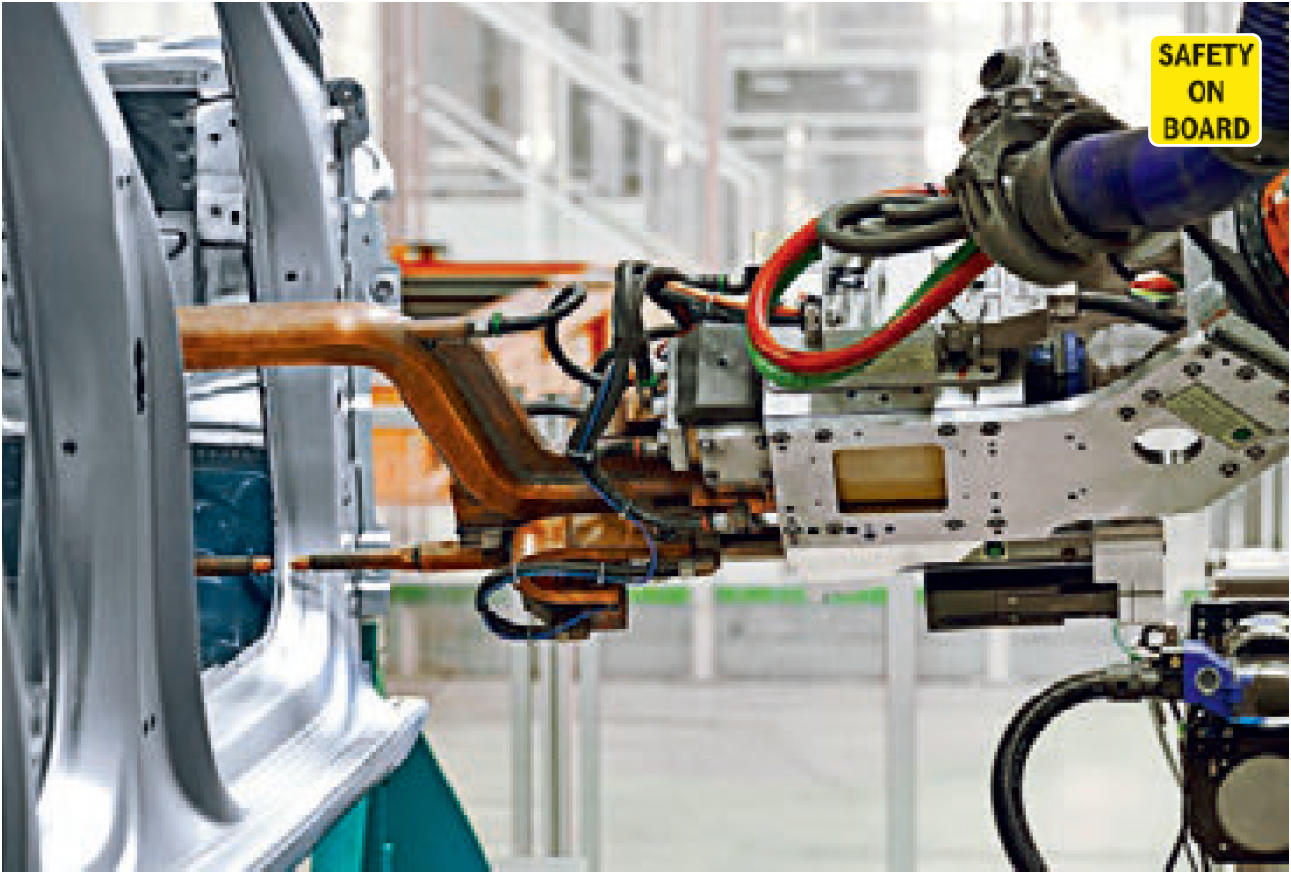

| In the body shop for its A3 model in Ingolstadt, Audi AG relies entirely on Rexroth solutions in joining technology. High quality, availability and safety are absolute musts. These are ensured by the PSI6000 welding controllers and the 350 nutrunners boasting a fully automated feature letting them switch from one point to the next. Audi produces 850 vehicles a day in the N60 assembly building, opened in 2012. Some 429 robots make around 4,500 spot welds – automatically and accurately – joining a wide range of sheet metal alloys. With adaptive control and integrated process monitoring, the PSI6000 possesses two important quality-assurance functions. Quality is also of the utmost importance when it comes to the numerous threaded connectors in the A3, 250 of which are deemed to be safety-critical. The high degree of automation, short cycle times and low space requirements necessitate automatic changing of nutrunners on the robots. The model 350 tightening system ensures quick and foolproof tool exchange. |

|

|

|