|

|

Self-Lubricating and Linear Bearing FAQ

Self-Lubricating Bearing Life Calculation

Service life of Self-Lubricating Bearings will vary depending on service environment, other conditions and the surface roughness of shaft at least . The following formula uses the relation of load and sliding distance. Note that the this formula should be used only as a reference.

Estimated Wear Amount (mm) : W = K×P×V×T . The following formula uses the relation of load and sliding distance. Note that the this formula should be used only as a reference.

Estimated Wear Amount (mm) : W = K×P×V×T

|

Specific wear K |

K:mm/(N/mm2・m/s・hr){mm/(kgf/cm2・m/min・hr)} |

|

Bearing pressure P |

P:N/mm2{kgf/cm2} |

|

Velocity V |

V:m/s{m/min} |

|

Running time T |

T:hr |

※Specific wear differs from each bearing. The bearing's specific wear is the value of bearing wear from testing divided by the test load, test velosity and test time.

Reference of specific wear by lubrication state

|

Lubrication state |

mm/(N/mm2・m/s・hr) |

mm/(kgf/cm2・m/min・hr) |

|

Non lubrication |

3×10-3~6×10-4 |

1~5×10-6 |

|

Periodical lubrication |

3×10-4~6×10-5 |

1~5×10-7 |

|

Oil lubrication |

3×10-5~6×10-6 |

1~5×10-8 |

※This formula is adopted from the perspective that wear is in proportion to the load and sliding distance. The influence of velocity and load, different modes of operation, type of lubricant used, clearance, surface roughness of mating material, invasion of foreign materials, etc.have not been taken into consideration.

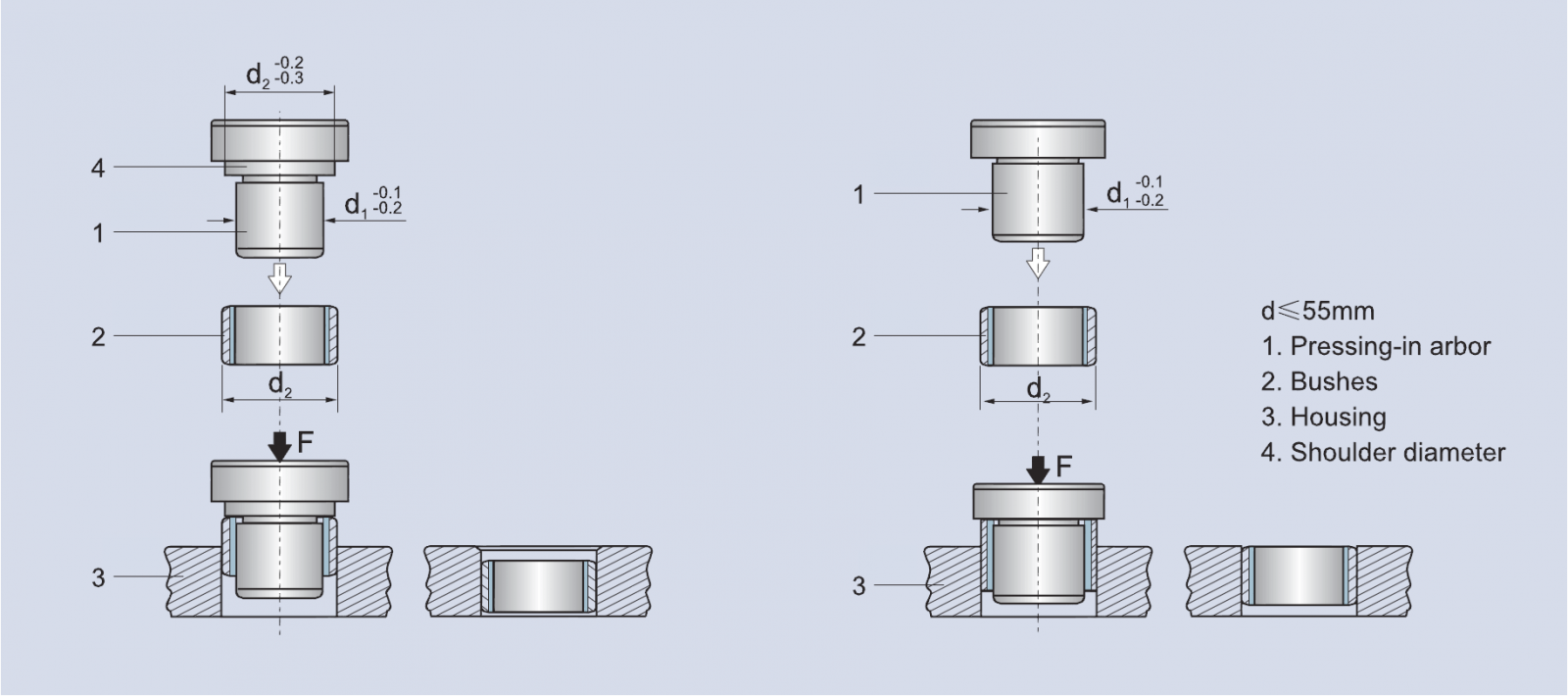

Self-Lubricating Installation Guide

|

Self-Lubricating Installation Guide |

|

|

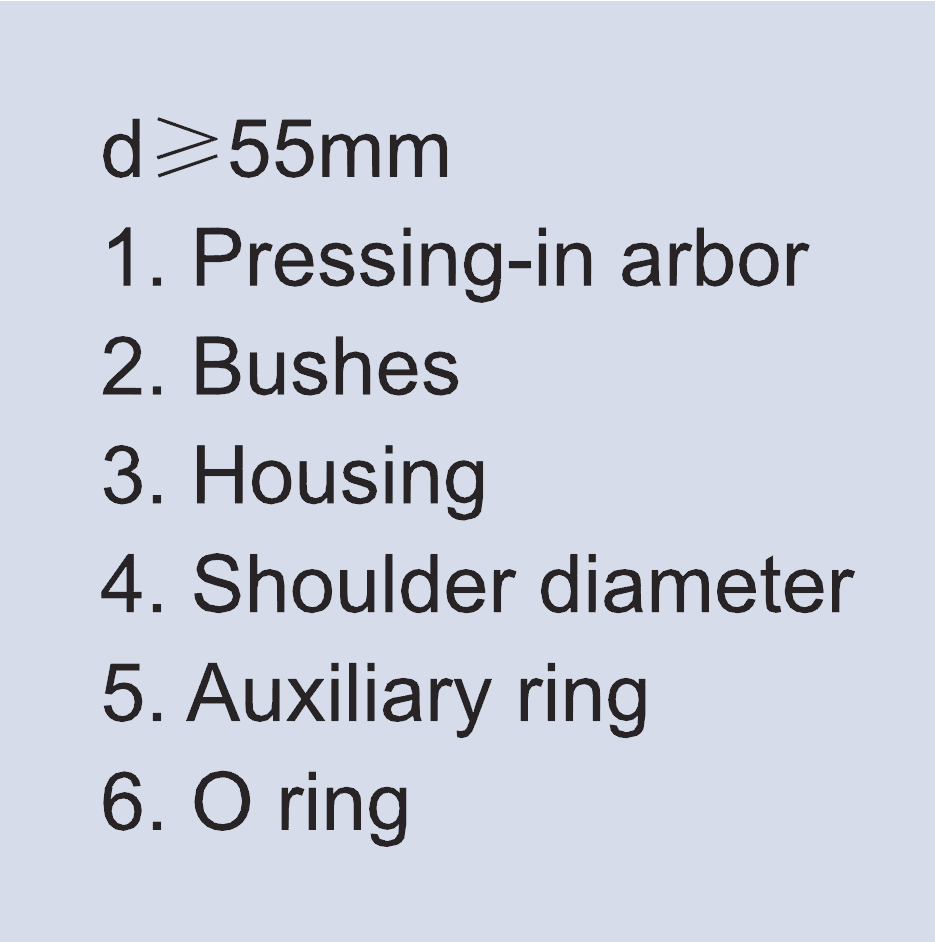

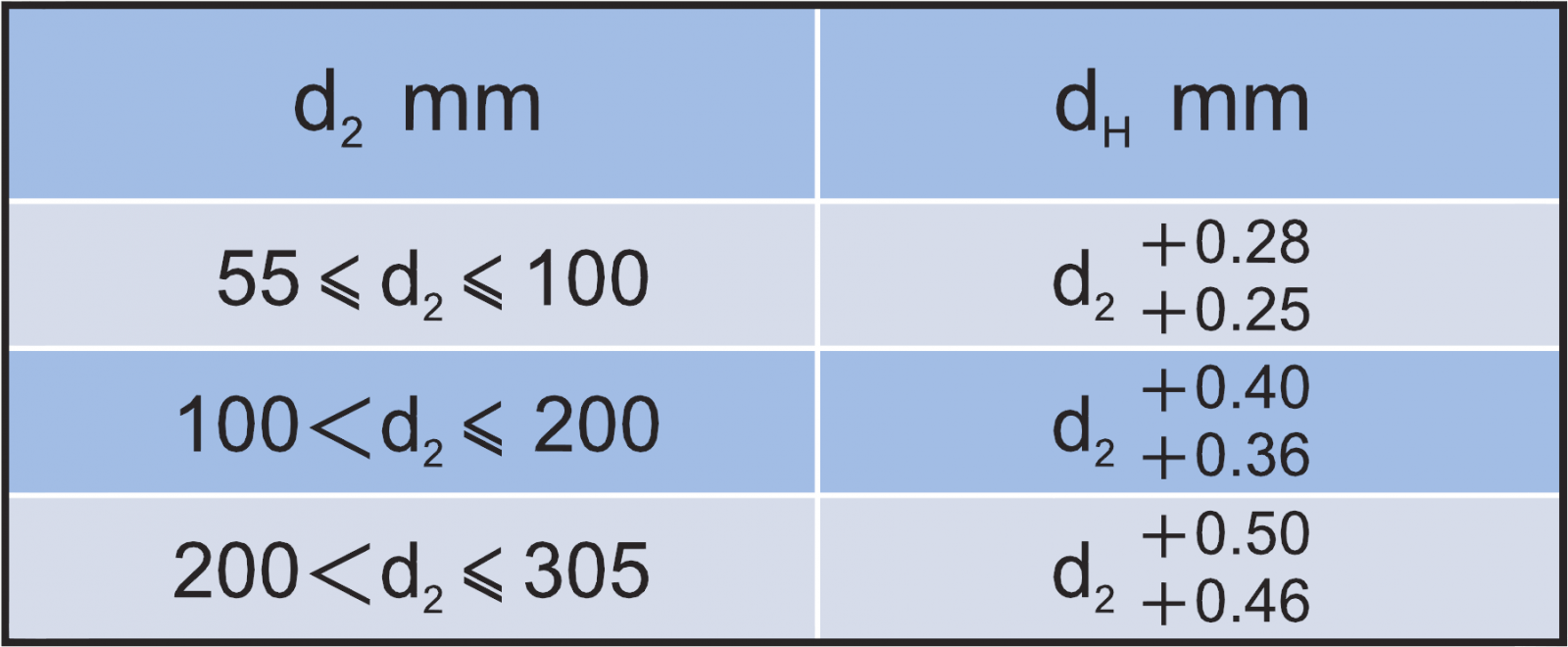

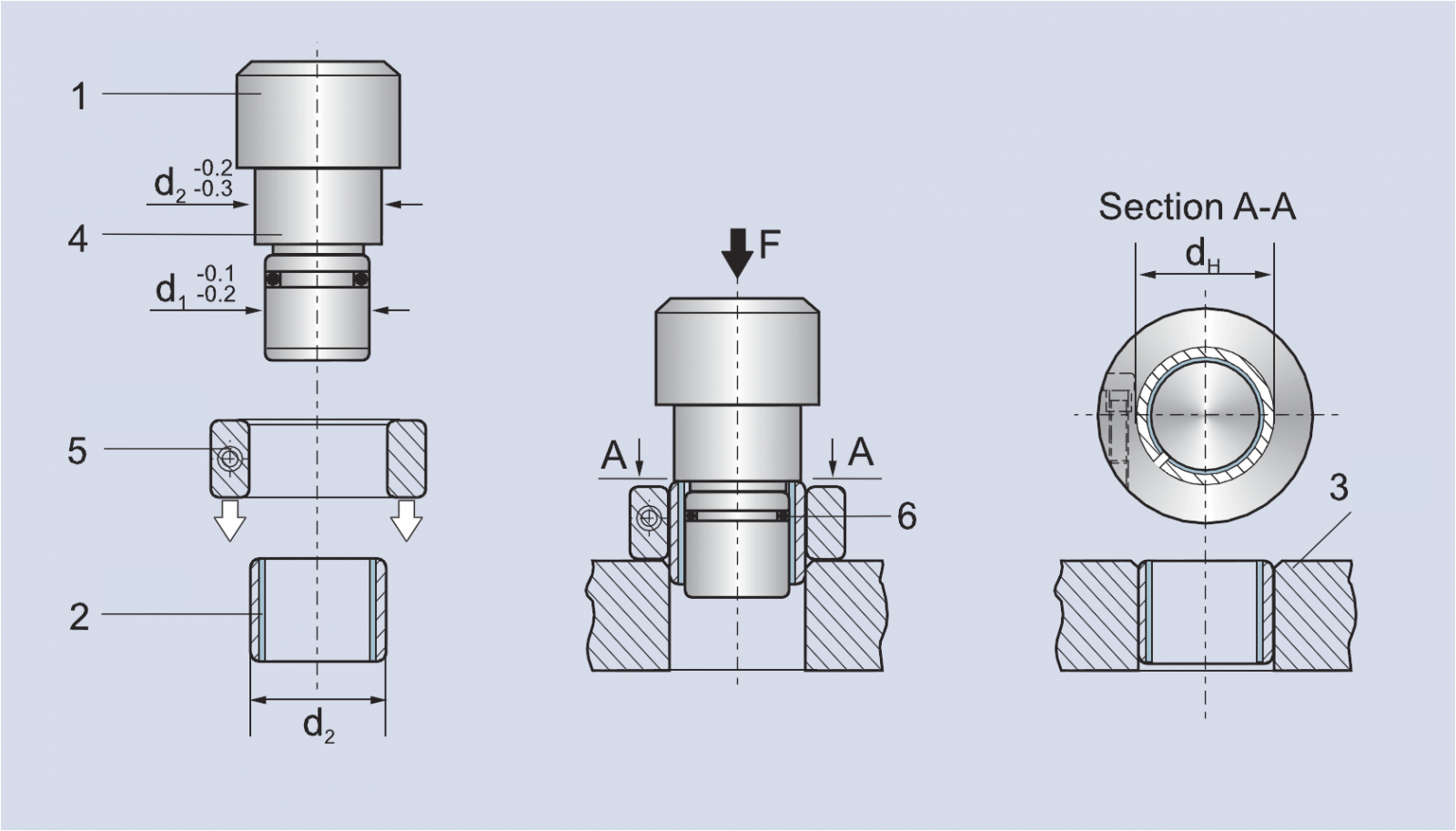

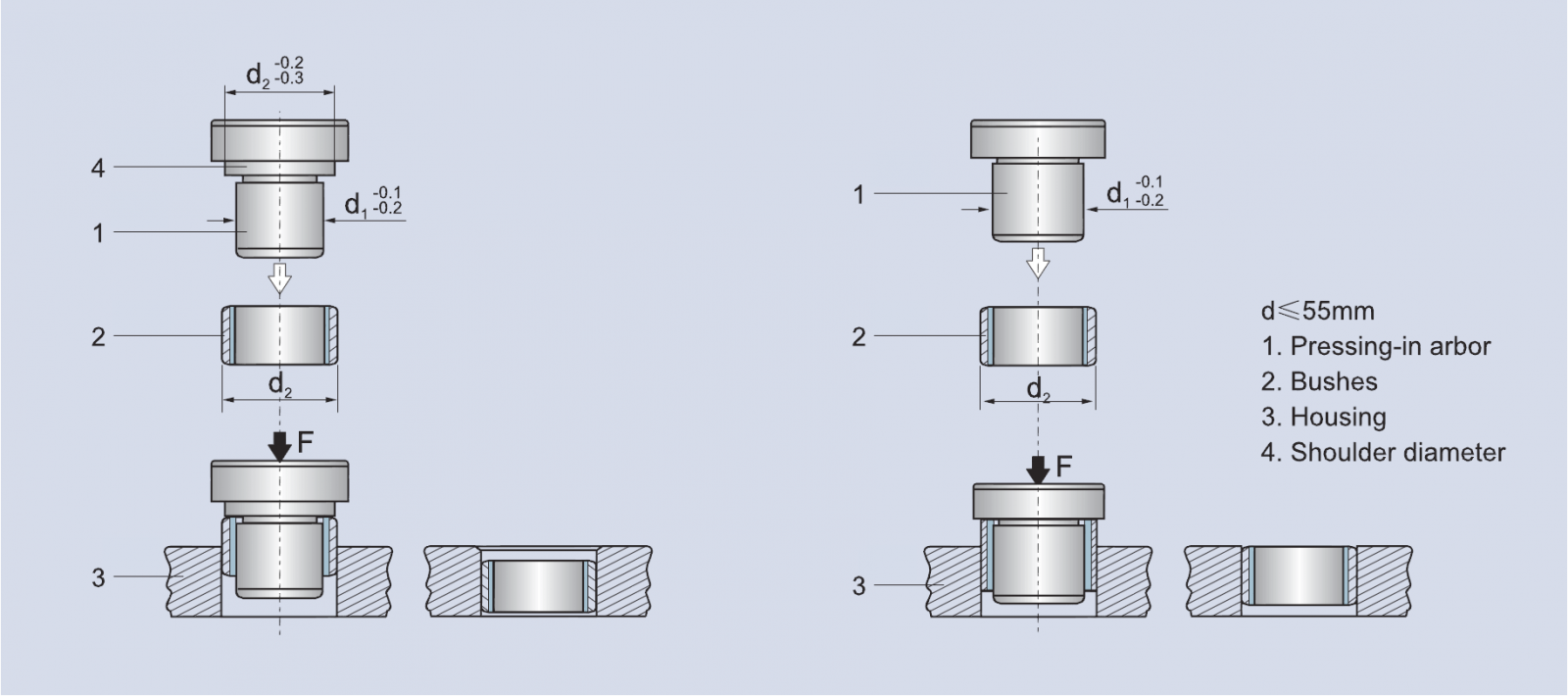

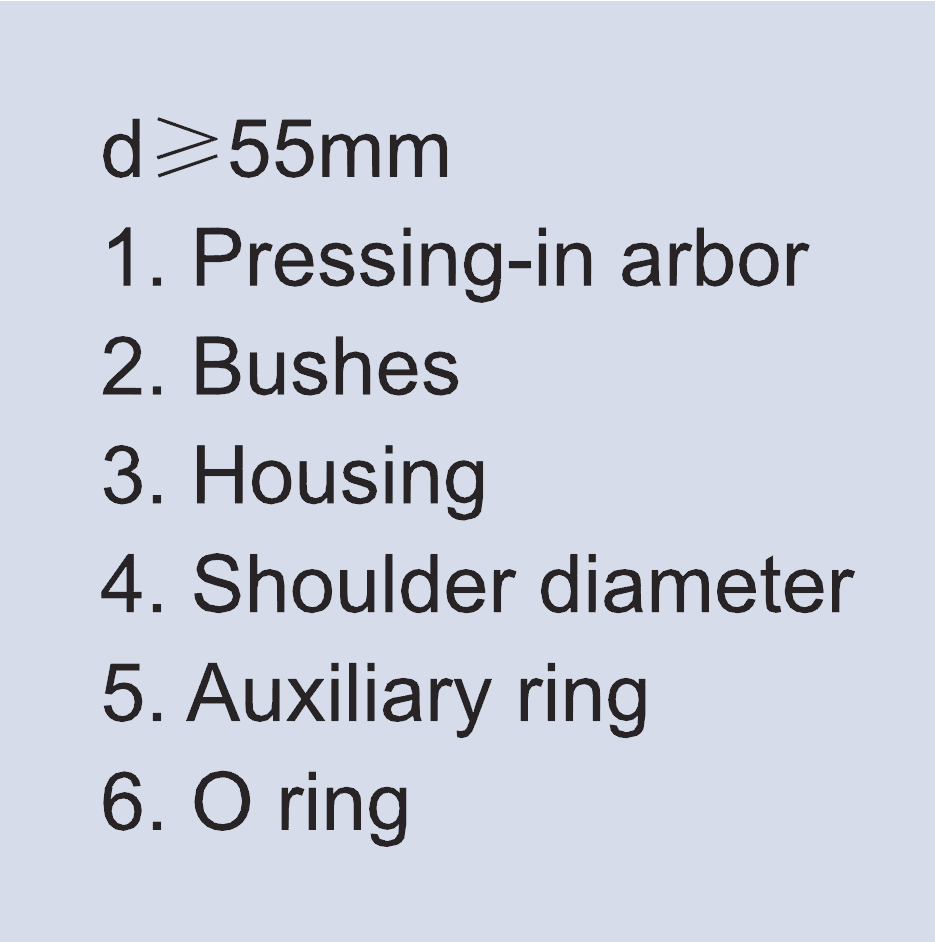

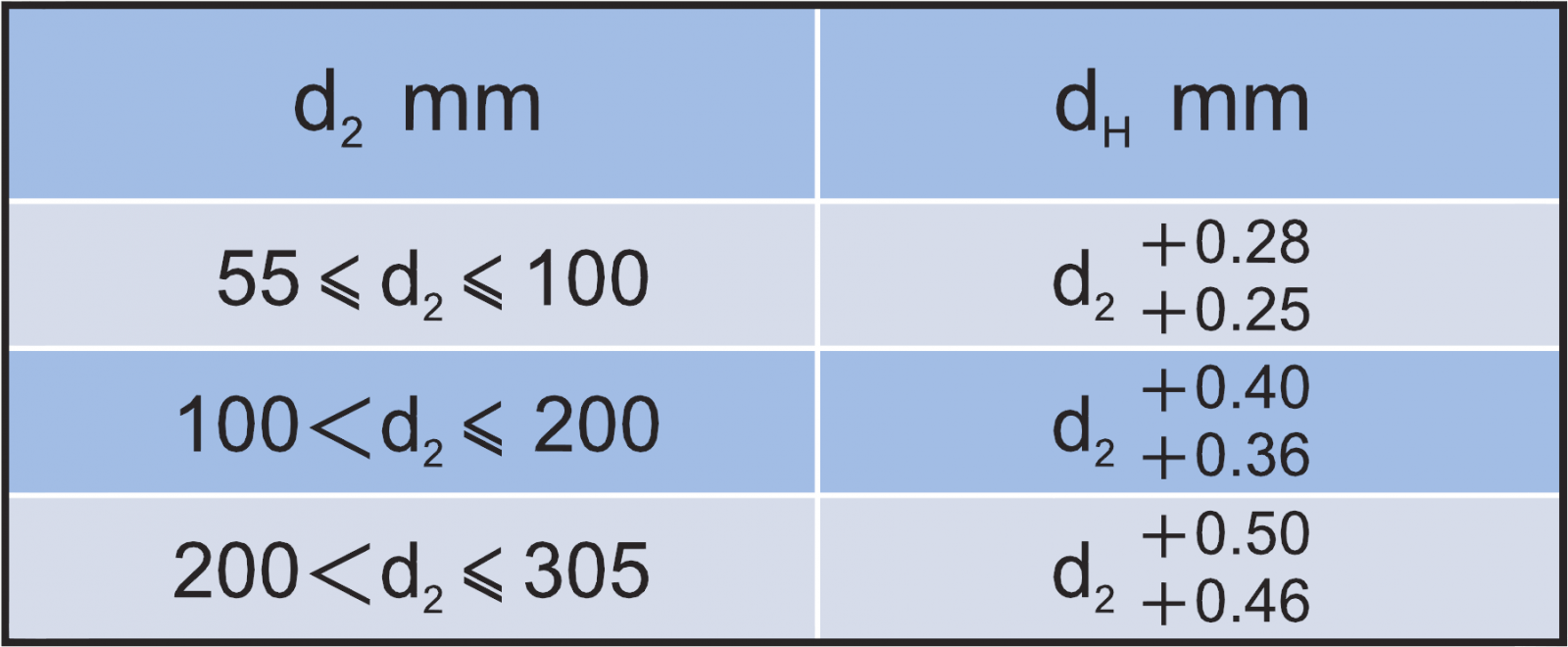

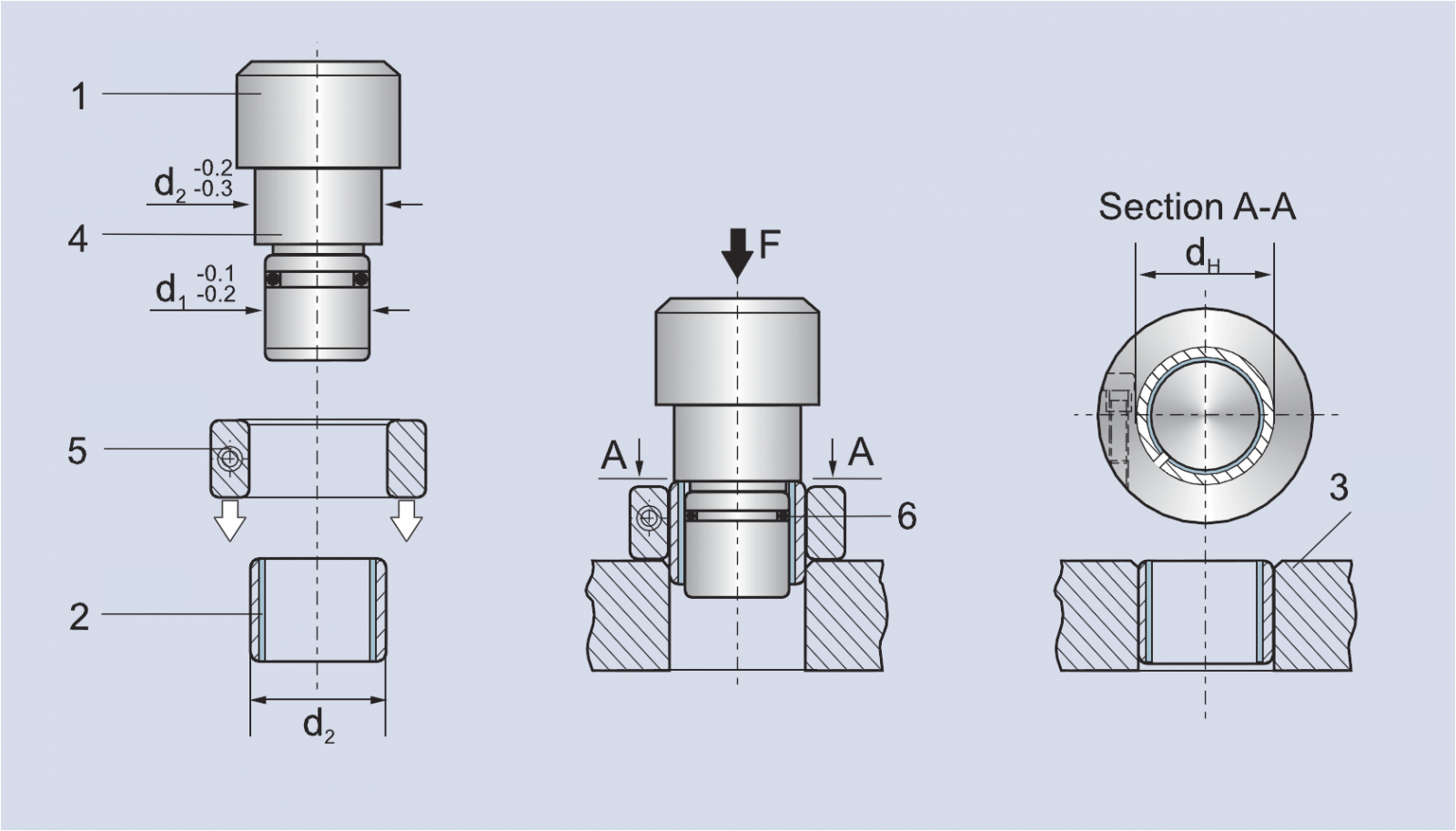

In most cases, our slide bearings are used with a press-fit in the same manner as general sleeve bearings. Fit the bearings into housings using mandrels or press. In case of a relatively large interference, provide both the I.D. of the housing and the O.D. of the bearing with chamfers, and fit the bearing into the housing with mandrel for easy installation. For some special application like 650# bushes for injection molding machines, can be used shrink fitting. |

|

|

|

|

. The following formula uses the relation of load and sliding distance. Note that the this formula should be used only as a reference.

. The following formula uses the relation of load and sliding distance. Note that the this formula should be used only as a reference.