Back

Back

Rexroth-Assembly Technology

|

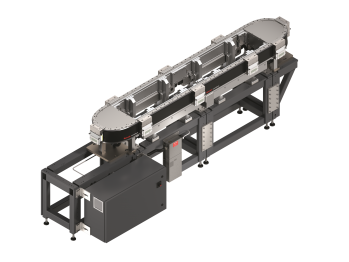

ActiveMover transfer system ActiveMover transfer system

|

Characteristics of the product:

PRECISION• High repeatability of +/- 0.01 mm

The integrated measuring system allows for precise indexing of the pallets, eliminating the need for additional lift and locate units. Stop positions can be configured in softwareanywhere around the system, even in curves. This feature greatly increases the process quality, productivity and efficiency.

FAST

• Speed up to 150 m / min

• Workpiece pallet change time 0.1 … 0.3 s dependent on pallet size and weight

• Acceleration up to 4 g

Due to the low friction, high propelling force between the magnetic linear drive and workpiece pallet, high speeds and rapid acceleration are achieved.In addition, there is no loss of time through stopping, positioning and indexing. The reduced cycle times strongly contribute to increased productivity at reduced cost.

ROBUST CARRIER

• Payload per workpiece pallet up to 10 kg

• Robust Cantilever Design

The unique pallet design allows easy access to pallets and fixtures from all sides. Tooling can work simultaneously above and underneath the pallets.Active Mover can generate propelling forces up to 160 N.

Because of the high payload per workpiece pallet up to 10 kg the ActiveMover can be used in many applications. Save cost by covering a large part of your manufacturing processes with one system and therefore standardizing the production equipment.

The ActiveMover - our conveying solution for a wide range of variants and small lot sizes or sensitive materials

Free programming and control of each individual workpiece pallet allows flexible realization of process flows.

The pallets can move back and forth, asynchronously and synchronously.

This offers maximum flexibility in retooling processes. Gentle movements , integrated collision avoidance and auto-queuing at workstations guarantee a smooth transport for sensitive products.